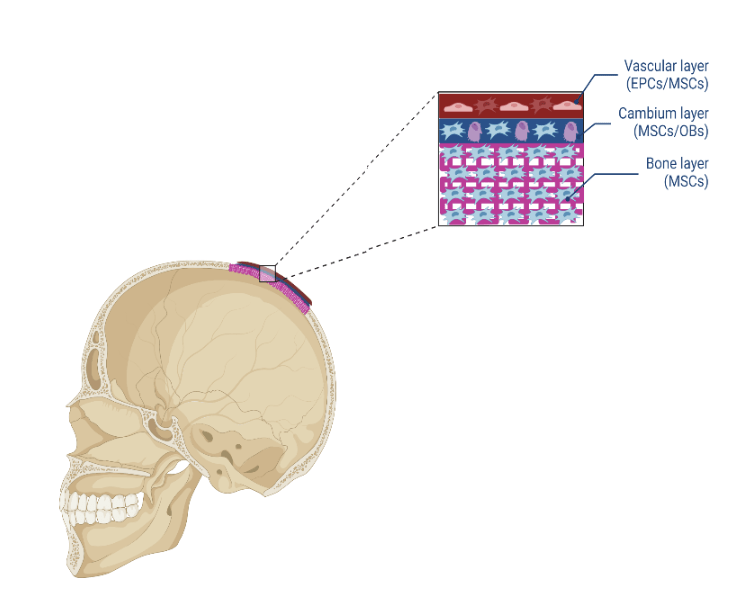

This project focuses on developing a 4D printing strategy to enhance bioprinting resolution to produce biomimetic thin membranous tissues, such as the periosteum. Bone defects, resulting from congenital abnormalities, disease, tumor resection, and traumatic injury, can result in severe implications for patient health and substantial healthcare costs. Traditional clinical techniques for bone defect repair include implantation of autografts. Researchers have developed a wealth of bone tissue engineering (BTE) strategies over the last several decades, but few have acknowledged the role of the periosteum in bone healing. The periosteum is a 100 µm thick sheath surrounding almost all bone tissue, consisting of an inner cambium layer, containing osteoprogenitor cell sources, and an outer fibrous layer, containing a dense collagen matrix, neural, and vascular networks. Periosteum is incredibly complex in its anatomy but remains a challenge to fabricate due to the stratified cell populations within such a small thickness. Therefore, this project aims to develop a 4D printing strategy to effectively enhance extrusion bioprinting resolution below its traditional 150 µm limitations to fabricate biomimetic periosteum. This is accomplished by harnessing charge interactions between anionic and cationic polymers, inducing a “shrinking” effect on printed hydrogel structures.